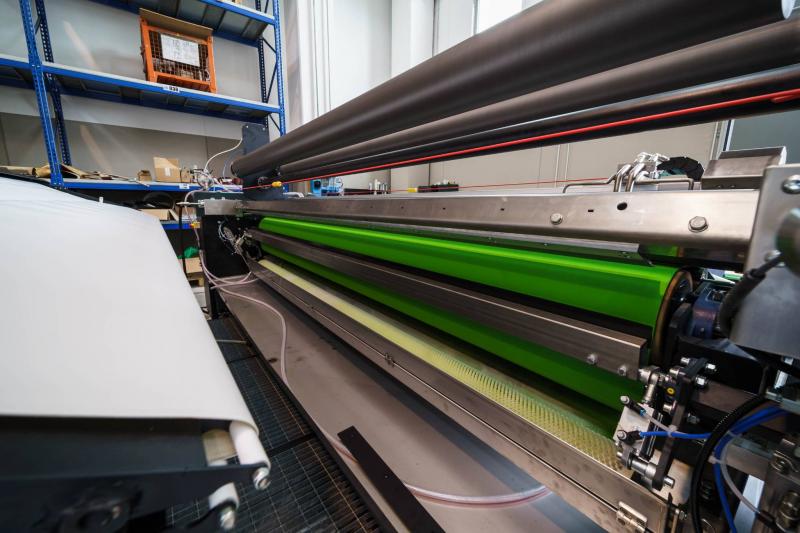

The machine J1 3400 has been designed to apply efficiently and very homogeneously a wide assortment of chemical products for finishing.

J1

3400

In REVERSE it is possible to spread :

- resins for the impregnation of shoe upper leathers and vehicle interiors

- hot and cold fatliquors and waxes

- aniline and dyestuffs

- filling agents, pre-base and high viscosity products (stucco) on splits, corrected and full grain leathers

- pigments of all types, also foamed, for base and colour coats

- water-based lacquers and topcoats

IN SINCRO it is possible to apply oils and waxes, both hot and cold, light coating, pigments and aniline dyes, design/printing/two-tone effects on printed (embossed) leathers; glues, sealing resins and flame-retardant products can be additionally applied on the flesh side.

It is possible to finish/upgrade goat & sheepskins, bovine side leathers, splits and whole hides, virtually covering the whole spectrum of leather items, from the thinnest (0.4 mm) and softest ones for clothing up to bovine leathers for furniture/ upholstery and car interiors in addition to thicker articles for footwear and leather goods.

Different geometries to choose from are displayed via touch screen in order to achieve more uniform or rather selective coatings. Based on:

- viscosity of the preparation

- leather grading and surface absorption capacity

- engraved cylinder's mesh and its relevant rpm

- pressure applied on the leather surface

It will be possible to accurately graduate the penetration of the chemical product and thereby shape the coating layer more or less superficially hence getting a softer and more natural article though effectively masking the leather defects without unwanted grain looseness.